PLA (polylactic acid) is a degradable 3D printing material. It has excellent comprehensive performance, economic benefits, printing model surface is fine and smooth, and not easy to warp deformation. Widely used in the market for a variety of printers.

Nozzle temperature(℃)

190℃ - 220℃

Bed temperature(℃)

40℃ - 60℃

Chamber temperature

Not required

Nozzle type

Brass nozzle

Print speed (mm/s)

40mm/s - 100mm/s

Cooling fan

ON

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

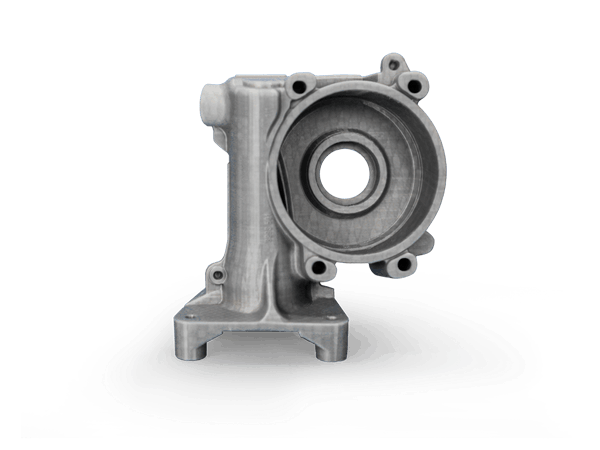

PLA-CF is a high strength modified PLA carbon fiber reinforced 3D printing consumable. It strengthens the tensile strength and impact strength of the raw material, while improving the dimensional stability of the print and the surface quality of the print. It is widely used in prototyping, conceptual models, end-use components and models with higher performance requirements.

Nozzle temperature(℃)

200℃ - 220℃

Bed temperature(℃)

40℃ - 60℃

Chamber temperature

Not required

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

30mm/s - 80mm/s

Cooling fan

ON

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

PETG (polyethylene terephthalate) is a copolymer modifier of ethylene glycol and PET. It is as easy to print as PLA. It has good toughness and chemical resistance, and the print has good layer adhesion. Suitable for printing all kinds of parts, can be used for mechanical parts, fixture, prototype design and so on.

Nozzle temperature(℃)

230℃ - 250℃

Bed temperature(℃)

80℃

Chamber temperature

Not required

Nozzle type

Brass nozzle

Print speed (mm/s)

40mm/s - 100mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

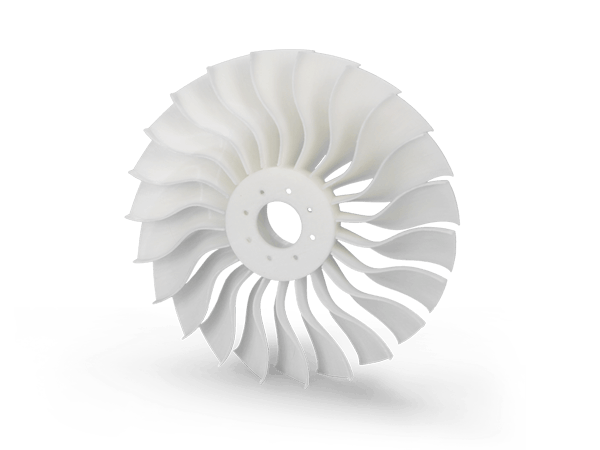

TPU-95A (thermoplastic polyurethane elastomer) is a flexible thermoplastic 3D printing material, which is a mature environmentally friendly material between rubber and plastic. It is flexible and has a wide hardness range, suitable for printing models for shock absorption, shock absorption and soft touch.

Nozzle temperature(℃)

210℃ - 230℃

Bed temperature(℃)

0℃ - 45℃

Chamber temperature

Not required

Nozzle type

Brass nozzle

Print speed (mm/s)

25mm/s - 50mm/s

Cooling fan

ON

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

PC (polycarbonate) is a solid transparent thermoplastic material. With the characteristics of high strength, high temperature resistance, impact resistance, bending resistance and other engineering plastics, can be used as final parts. Usually used in the production of shell parts, rigid parts and fixtures.

Nozzle temperature(℃)

250℃ - 290℃

Bed temperature(℃)

80℃ - 110℃

Chamber temperature(℃)

50℃

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

25mm/s - 80mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

WAX is a kind of high precision resin material. The surface of the printing model is smooth and delicate, no need for second processing and polishing. With excellent casting properties, can be fast melting, no dust or residue. Mainly used in jewelry, collectibles, machinery parts and other precision investment casting fields.

Nozzle temperature(℃)

245℃ - 265℃

Bed temperature(℃)

90℃ - 100℃

Layer height(mm)

0.1mm - 0.2mm

Nozzle type

Brass nozzle

Print speed

25mm/s - 90mm/s

Cooling fan

ON

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

ABS (acrylonitrile butadiene styrene) is a common engineering material for 3D printing. It is cheap, and has good comprehensive mechanical properties, hot melt and impact strength. Widely used in manufacturing industry and chemical industry.

Nozzle temperature(℃)

240℃ - 260℃

Bed temperature(℃)

80℃ - 100℃

Chamber temperature(℃)

OFF/50℃

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

20mm/s - 80mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

ASA has similar mechanical properties to ABS, but ASA has excellent UV resistance and is commonly used in outdoor and automotive applications.

Nozzle temperature(℃)

250℃ - 270℃

Bed temperature(℃)

90℃ - 110℃

Chamber temperature(℃)

50℃

Dry temperature

100℃/4小时

Print speed (mm/s)

20mm/s - 80mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

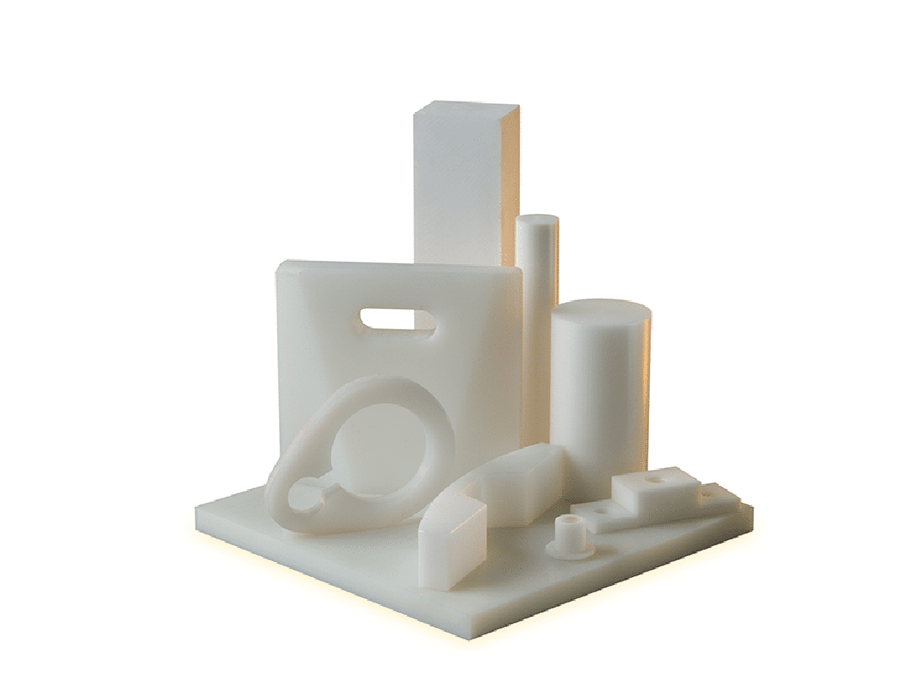

PVDF (polyvinylidene difluoride) is a high-performance polymer with excellent chemical, heat and wear resistance, ideal for applications in harsh environments.

Nozzle temperature(℃)

245℃ - 265℃

Bed temperature(℃)

90℃ - 110℃

Chamber temperature(℃)

Not required

Nozzle type

Brass nozzle

Print speed (mm/s)

40mm/s - 60mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

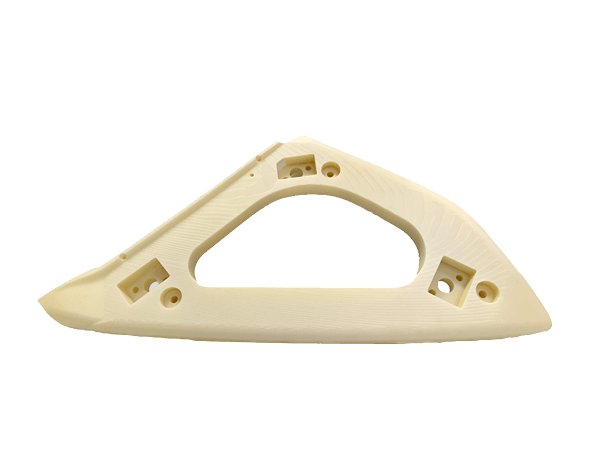

Ultra PA (High Temperature Polyamide) is a special high temperature nylon 3D printing material. High wear resistance, toughness, higher strength and durability, as well as good heat resistance and lower moisture absorption, make high temperature nylon an ideal choice for a variety of 3D printing applications. Print surface feel smooth, good dimensional stability.

Nozzle temperature(℃)

280℃ - 300℃

Bed temperature(℃)

70℃ - 80℃

Chamber temperature(℃)

Not required

Dry temperature

100℃/10小时

Print speed (mm/s)

30mm/s - 90mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

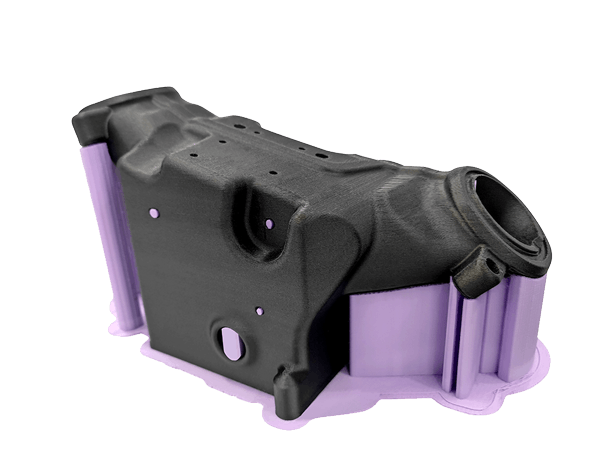

Ultra PA-CF (High Temperature Polyamide Carbon Fiber Reinforced) is a high temperature nylon base 15% cropped carbon fiber reinforced 3D printing material. It has the characteristics of low moisture absorption, high strength, high wear resistance, excellent chemical resistance and high heat resistance. Good dimensional stability in the printing process, no edge warping problem, suitable for the industrial field of finished parts.

Nozzle temperature(℃)

280℃ - 320℃

Bed temperature(℃)

70℃ - 80℃

Chamber temperature(℃)

50℃/off

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

30mm/s - 60mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

Ultra PA-GF (High Temperature Polyamide Glass Fiber Reinforced) is a high temperature nylon based 15% cropped glass fiber reinforced 3D printing material. The addition of glass fiber improves the mechanical properties, heat resistance, dimensional stability of nylon, reduces shrinkage, warping, and better layer adhesion.

Nozzle temperature(℃)

280℃ - 320℃

Bed temperature(℃)

70℃ - 80℃

Chamber temperature(℃)

50℃/off

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

30mm/s - 60mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

PET-CF is specially developed for FDM 3D printing process, and its substrate material is PET engineering plastic with low moisture absorption, high strength, creep resistance, excellent chemical resistance and high heat resistance. With good dimensional stability, no warpage and no shrinkage and no smell, no heating chamber are required during the printing process.

Nozzle temperature(℃)

280℃ - 320℃

Bed temperature(℃)

70℃ - 90℃

Chamber temperature(℃)

50℃/off

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

30mm/s - 90mm/s

Cooling fan

OFF/Low

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

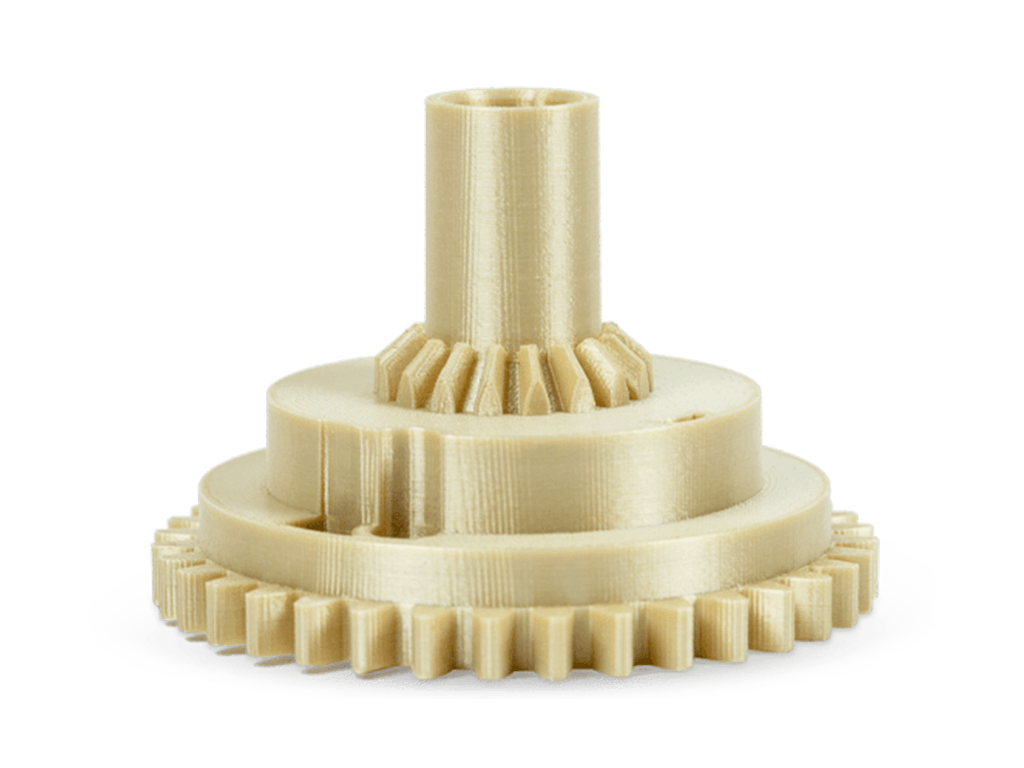

PEEK (polyether ether ketone) is an organic thermoplastic polymer with a variety of mechanical properties such as high temperature performance, mechanical strength and excellent chemical resistance. It can be used in aerospace, medical, petroleum industry and advanced mechanical engineering fields.

Nozzle temperature(℃)

400℃ - 450℃

Bed temperature(℃)

120℃ - 150℃

Chamber temperature(℃)

70℃-120℃

Layer height(mm)

0.1mm-0.15mm

Print speed (mm/s)

20mm/s - 40mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

PEEK-CF is a kind of carbon fiber reinforced PEEK material, which is a kind of high-end thermoplastic composite material. After carbon fiber reinforced polyether ether ketone has further improved in mechanical properties, chemical corrosion resistance, radiation resistance and high temperature resistance. It can replace metal parts in many occasions to achieve light weight and high strength.

Nozzle temperature(℃)

400℃ - 450℃

Bed temperature(℃)

100℃ - 160℃

Chamber temperature(℃)

70℃-120℃

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

20mm/s - 50mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

PEEK-GF is a glass fiber reinforced PEEK material with high strength, high Rigidity and high temperature resistance, and better toughness than carbon fiber. Widely used in lightweight high strength, wear resistance, high temperature resistant parts.

Nozzle temperature(℃)

400℃ - 450℃

Bed temperature(℃)

100℃ - 150℃

Chamber temperature(℃)

70℃-120℃

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

20mm/s - 50mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

PEI 1010 is a polyether imide plastic with high tensile strength, chemical resistance and heat resistance. It can contact with food and reach food safety level. PEI also has excellent flame retardant, flame retardant grade can reach UL94V-0. Widely used in food and drug packaging, medical equipment, auto parts and other fields.

Nozzle temperature(℃)

360℃ - 390℃

Bed temperature(℃)

140℃ - 220℃

Chamber temperature(℃)

70℃-120℃

Layer height(mm)

0.1mm-0.15mm

Print speed (mm/s)

20mm/s - 40mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

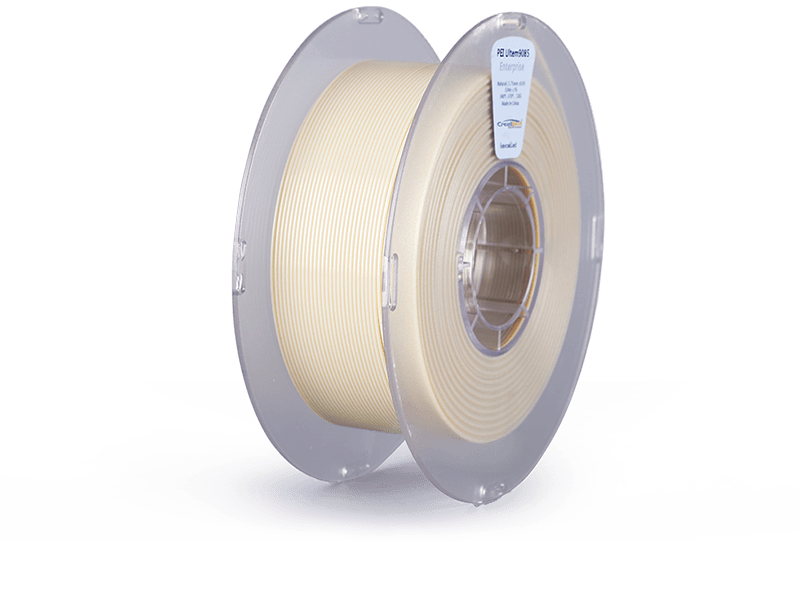

PEI 9085 is an aviation grade polymer with excellent heat resistance, chemical resistance, high strength and excellent flame retardant. It is very suitable for printing flame retardant components, suitable for aircraft interiors, piping systems, electrical enclosures and other fields.

Nozzle temperature(℃)

320℃ - 350℃

Bed temperature(℃)

140℃ - 220℃

Chamber temperature(℃)

90℃-120℃

Layer height(mm)

0.1mm-0.15mm

Print speed (mm/s)

20mm/s - 50mm/s

Cooling fan

OFF

Mechanical stability at high temperature

Deformation resistance under external force

Impact resistance under impact

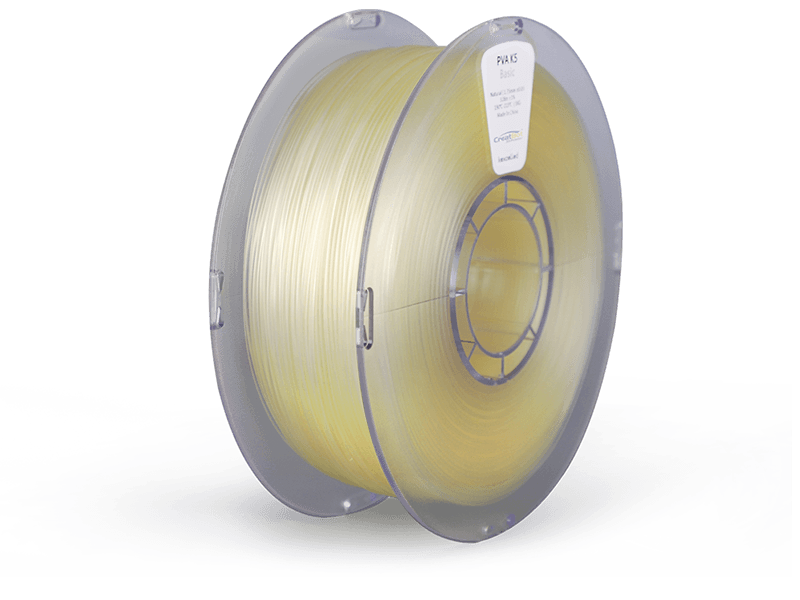

PVA (polyvinyl alcohol) is a water-soluble 3D printing support material that can be well bonded to PLA, PA, PETG and other materials. It is non-toxic and odorless during the printing, can be dissolved in water, and is environmentally friendly and non-polluting.

Nozzle temperature(℃)

180℃ - 220℃

Bed temperature(℃)

45℃ - 60℃

Chamber temperature(℃)

Not required

Nozzle type

Brass nozzle

Print speed (mm/s)

20mm/s - 40mm/s

Cooling fan

ON

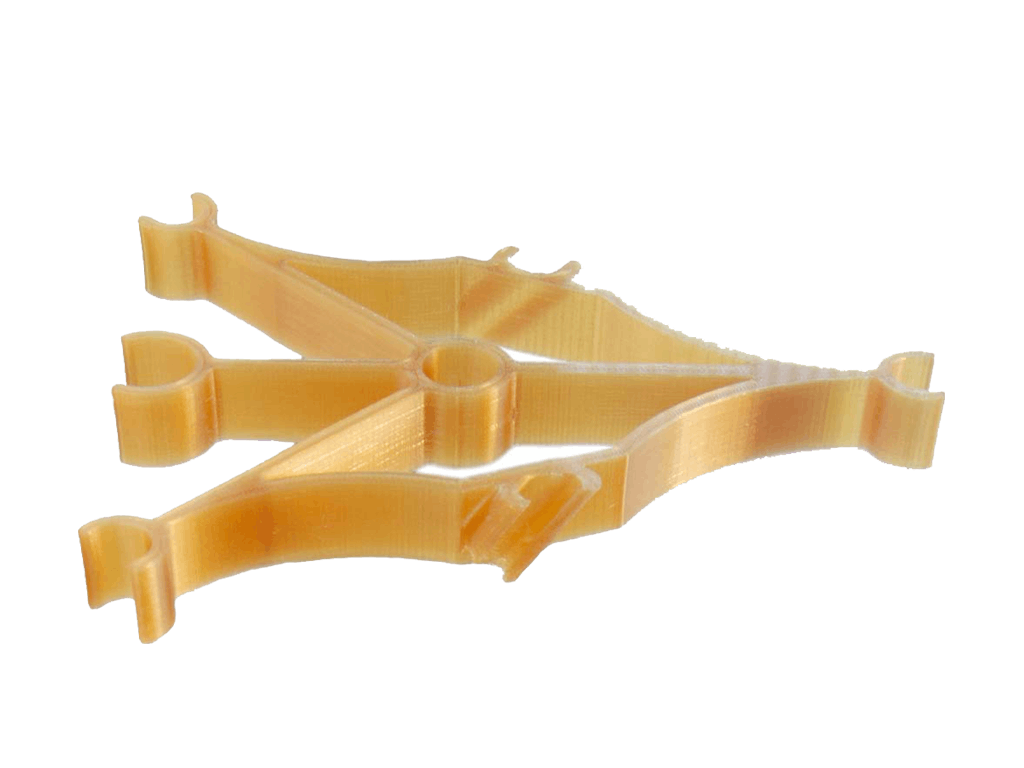

S-270 is a quick and easy to remove support material. By adjusting the bonding strength between the support surface of the main material and the S-270, the quick and easy remove can be realized. No water or solvent is required when removing the support, which does not cause water pollution and is safe and environmental protection.

Nozzle temperature(℃)

280℃ - 290℃

Bed temperature(℃)

60℃ - 80℃

Chamber temperature(℃)

Not required

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

30mm/s - 120mm/s

Cooling fan

ON

S-350 is a quick and easy to remove support material. By adjusting the bonding strength between the support surface of the main material and the S-350, the quick and easy remove can be realized. No water or solvent is required when removing the support, which does not cause water pollution and is safe and environmental protection.

Nozzle temperature(℃)

280℃ - 290℃

Bed temperature(℃)

60℃ - 80℃

Chamber temperature(℃)

Not required

Nozzle type

Hardened steel nozzle

Print speed (mm/s)

30mm/s - 120mm/s

Cooling fan

ON